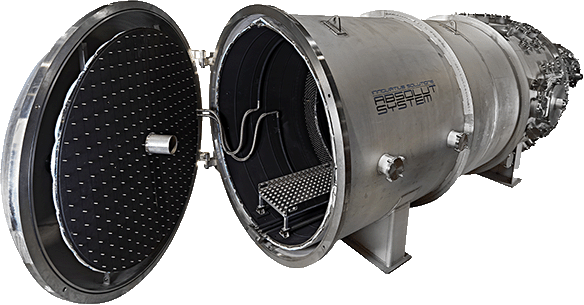

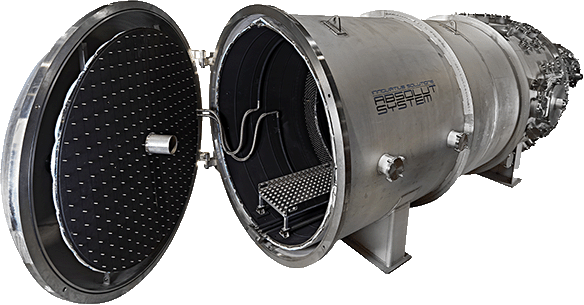

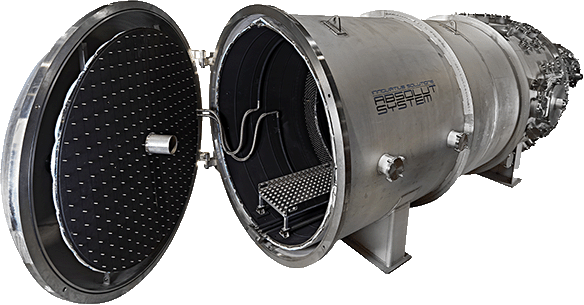

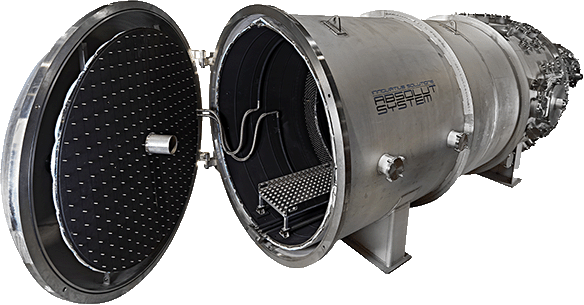

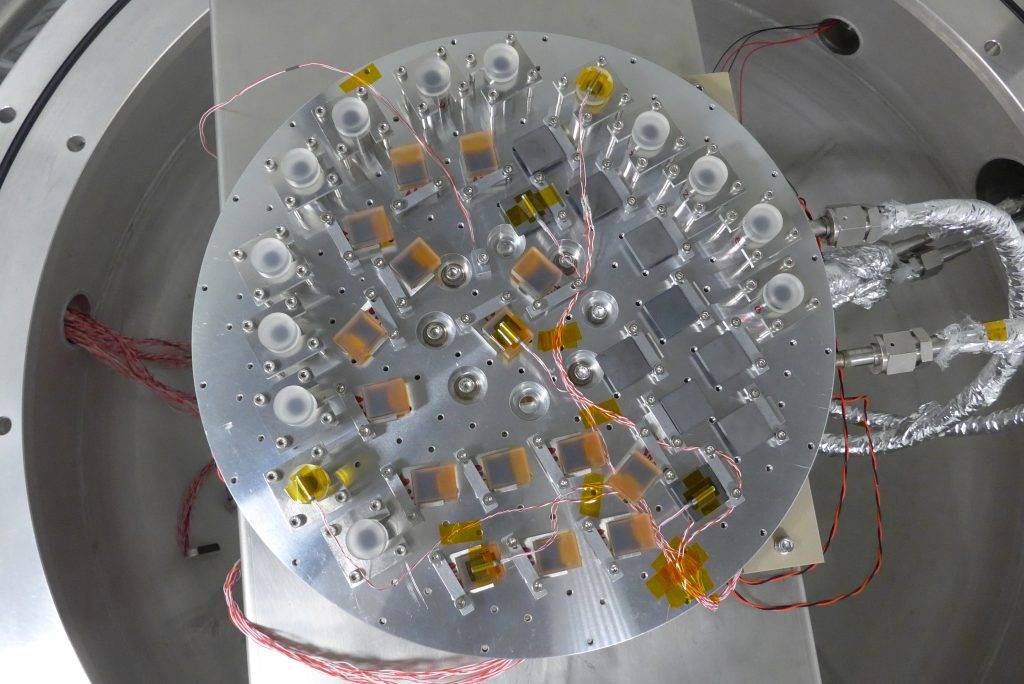

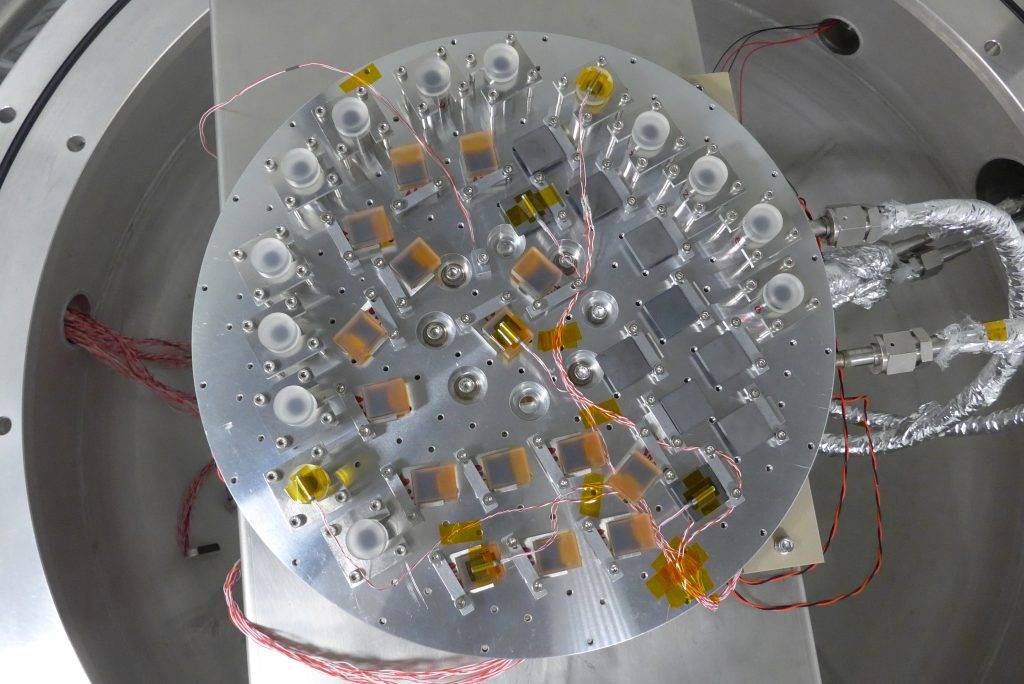

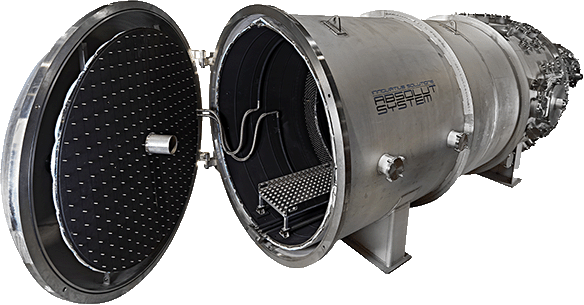

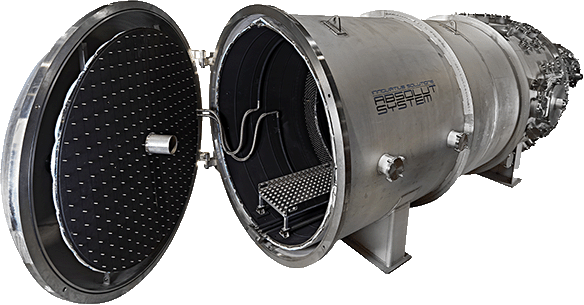

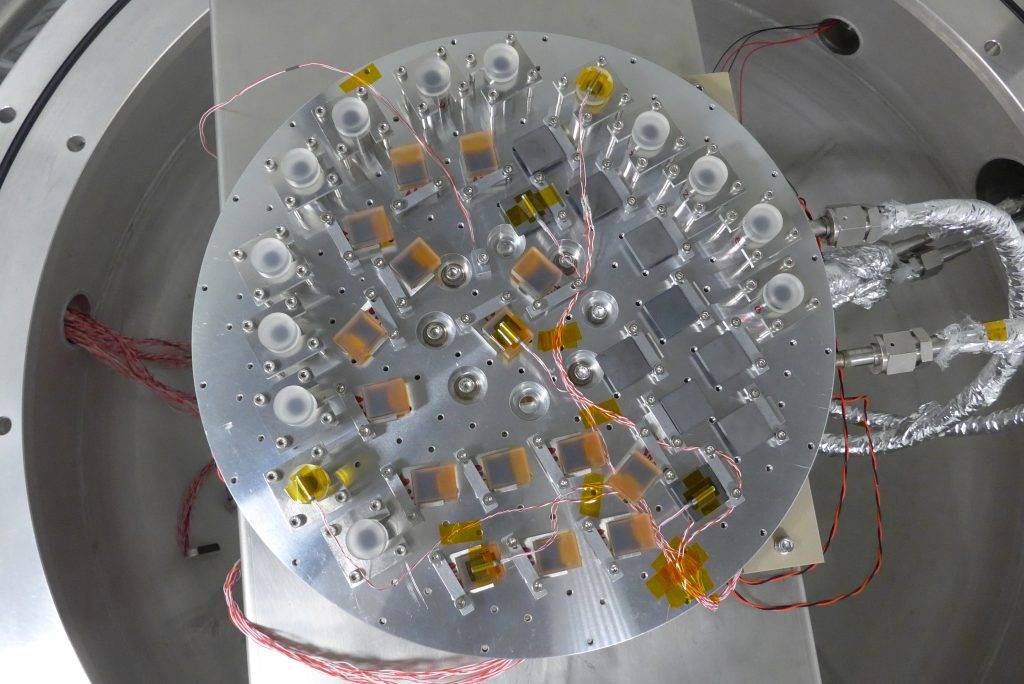

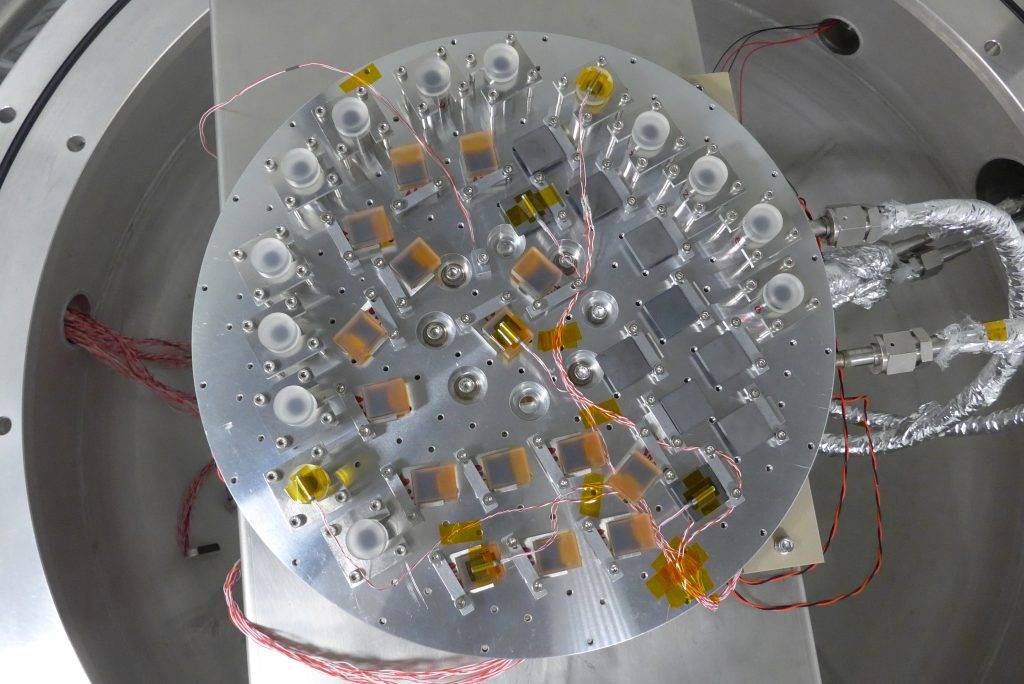

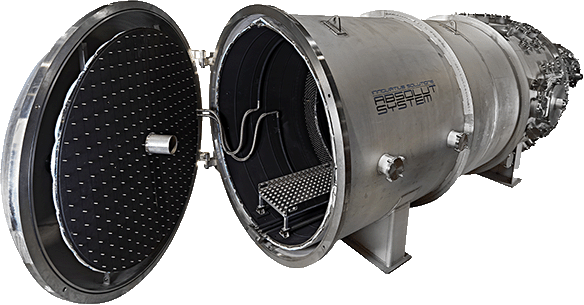

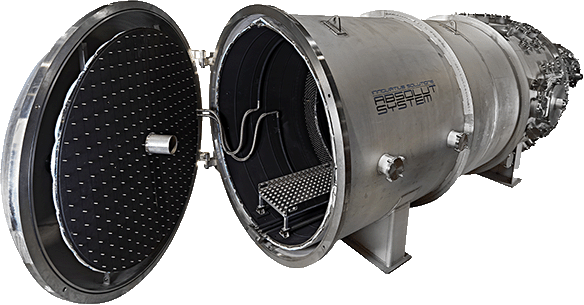

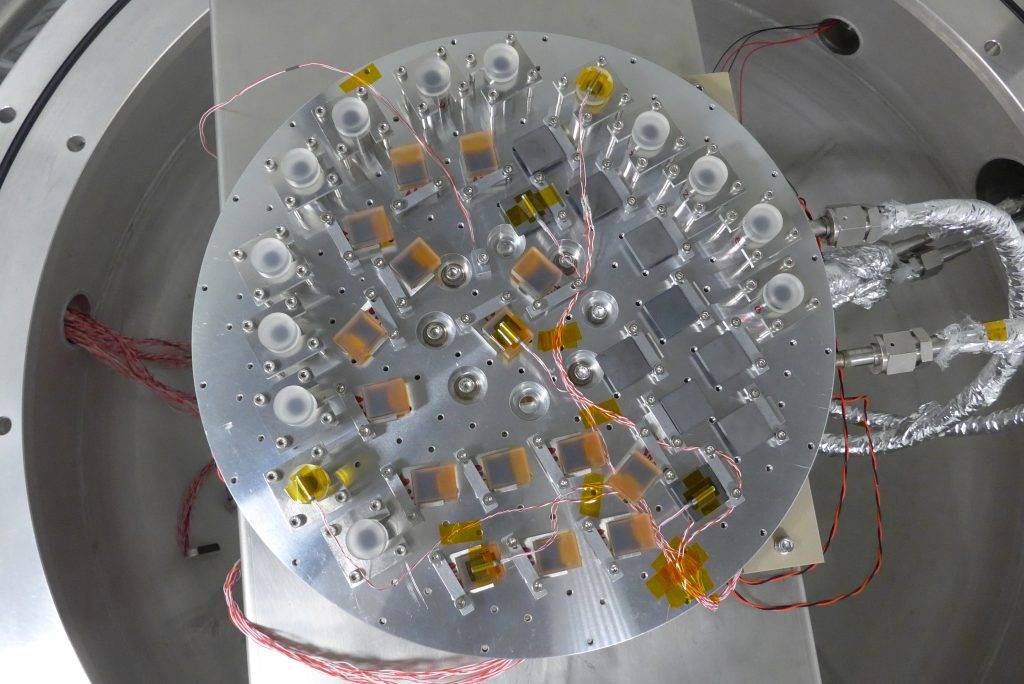

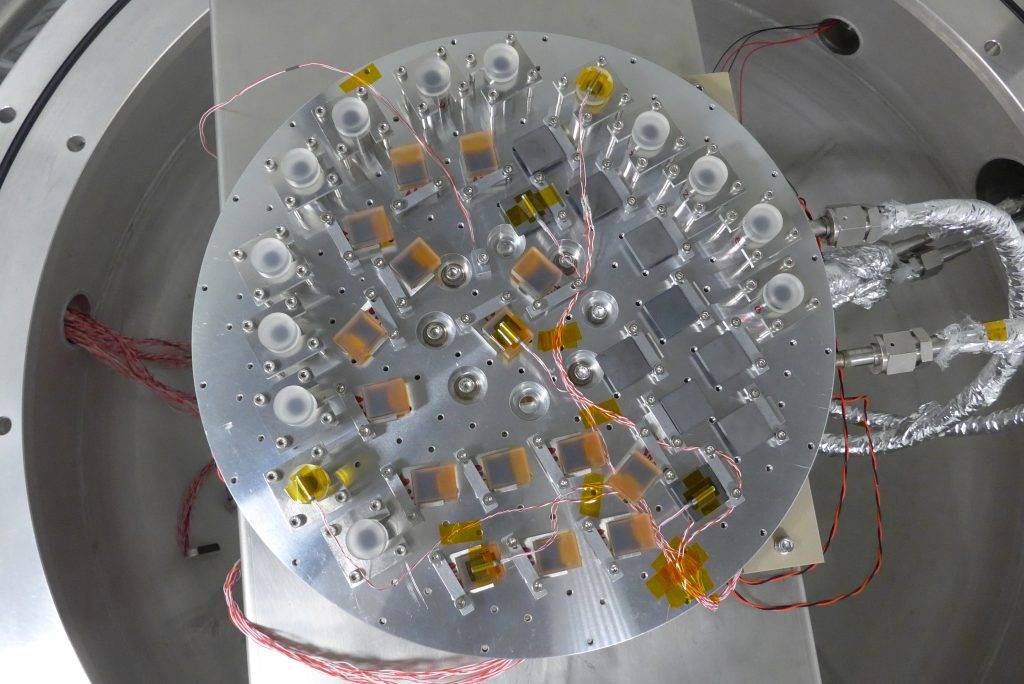

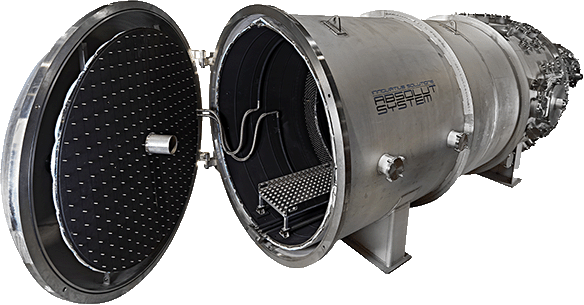

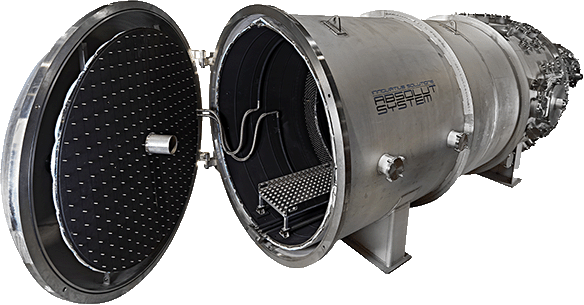

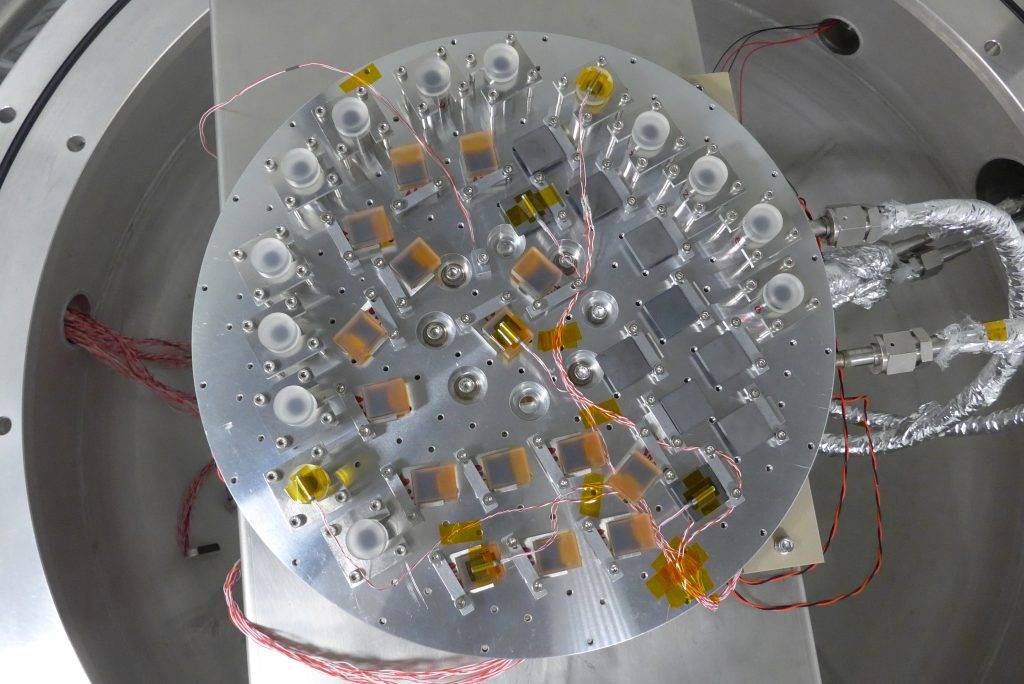

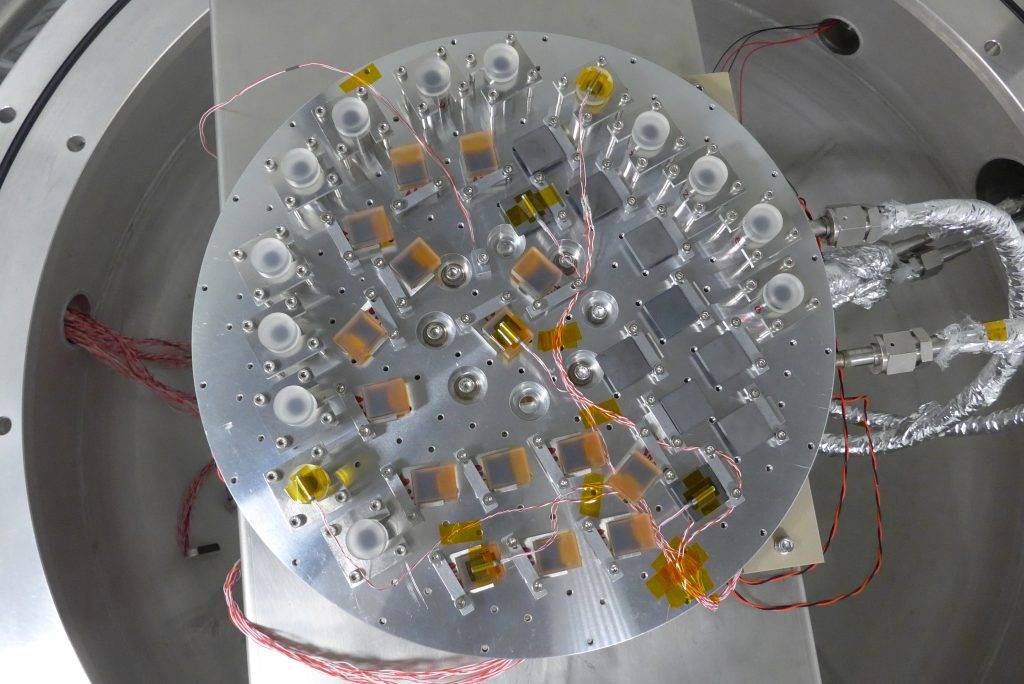

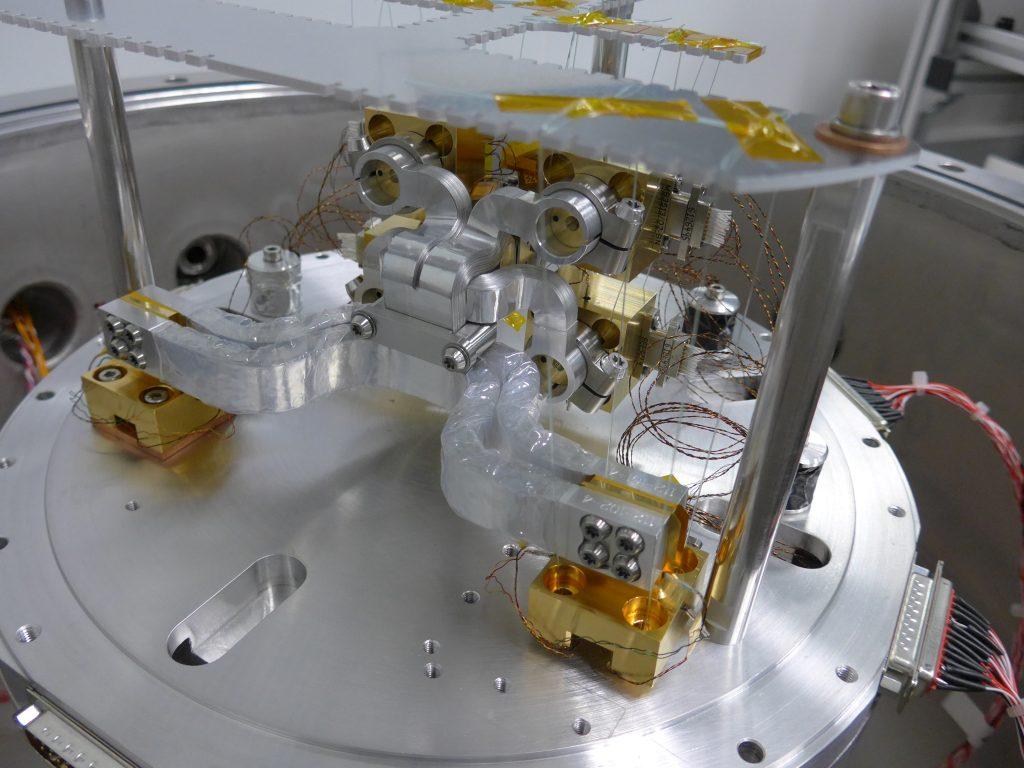

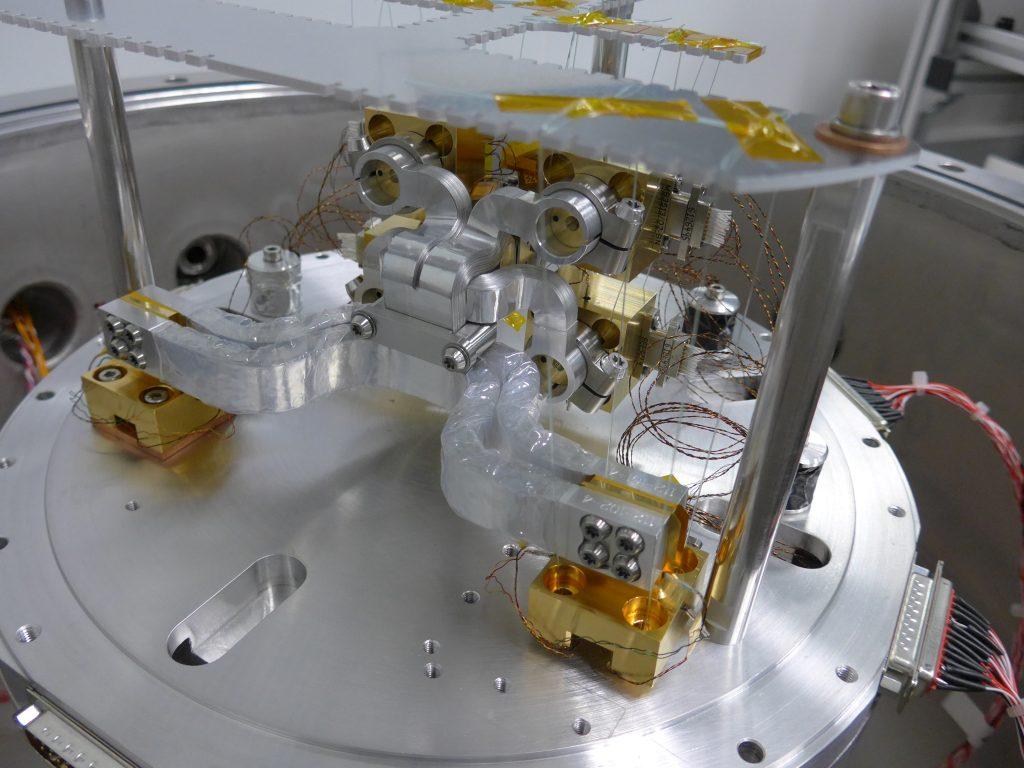

Thermal vacuum test benches equipped with Gilfford-McMahon coolers (from 20K to 373K) or a cryogenic cooling loop.

Absolut System has several test facilities to qualify components for deep thermal cycling (20K – 300K).

Vacuum test benches

Thermal vacuum test benches equipped with Gilfford-McMahon coolers (from 20K to 373K) or a cryogenic cooling loop.

Thermal cycling

Thermal cycling for sample/process qualification (from 30K to 373K).

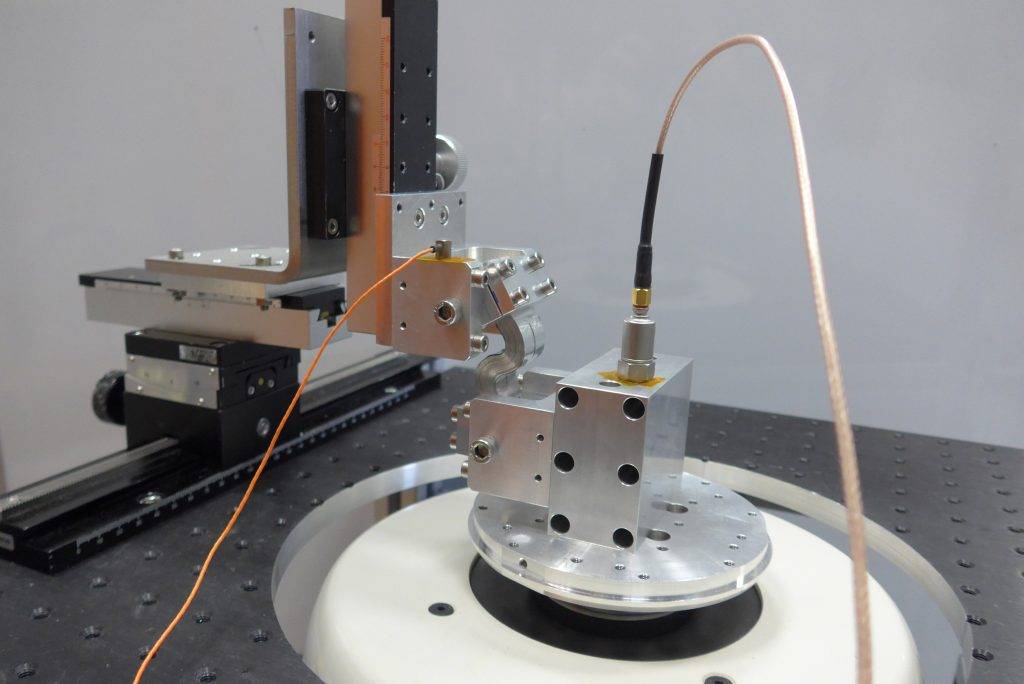

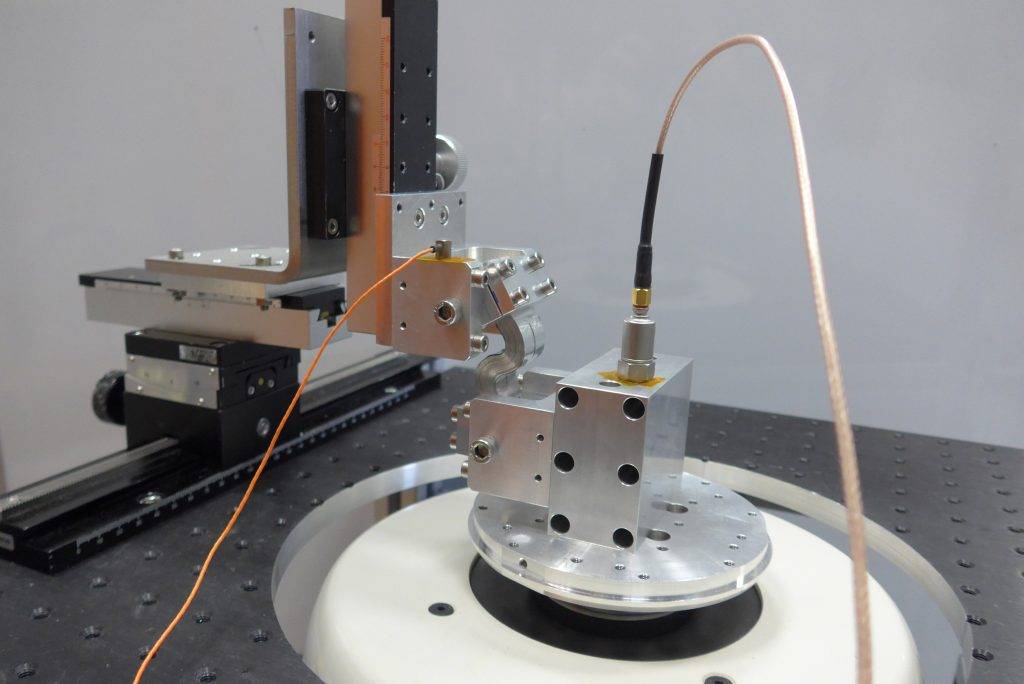

Mechanical test benches

Mechanical test benches: stiffness, vibration, damping for structural validation.

Thermal testing

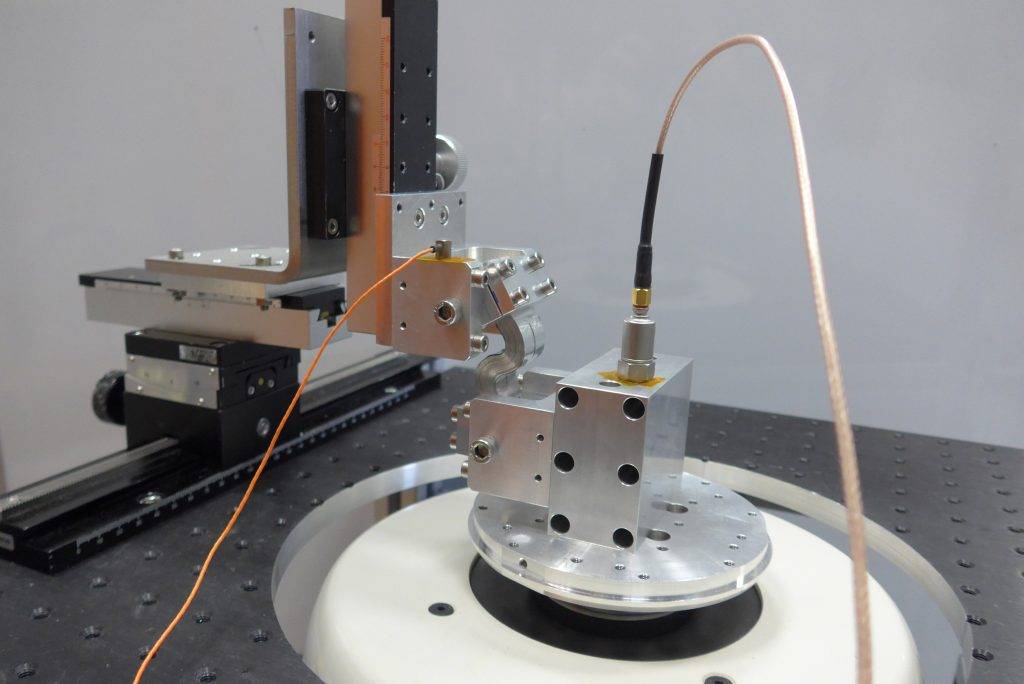

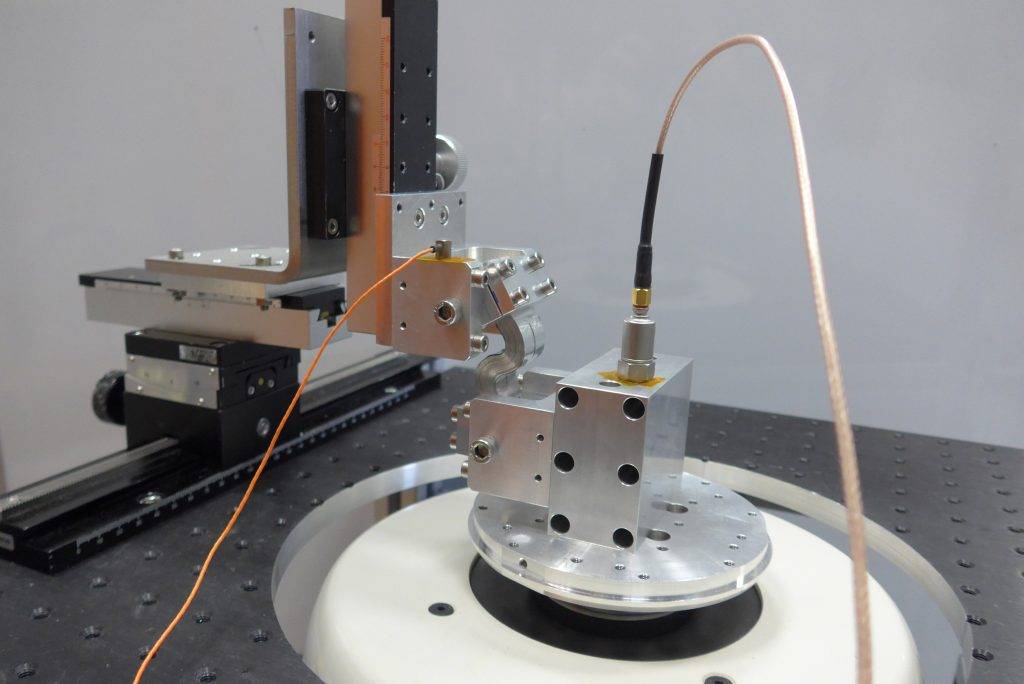

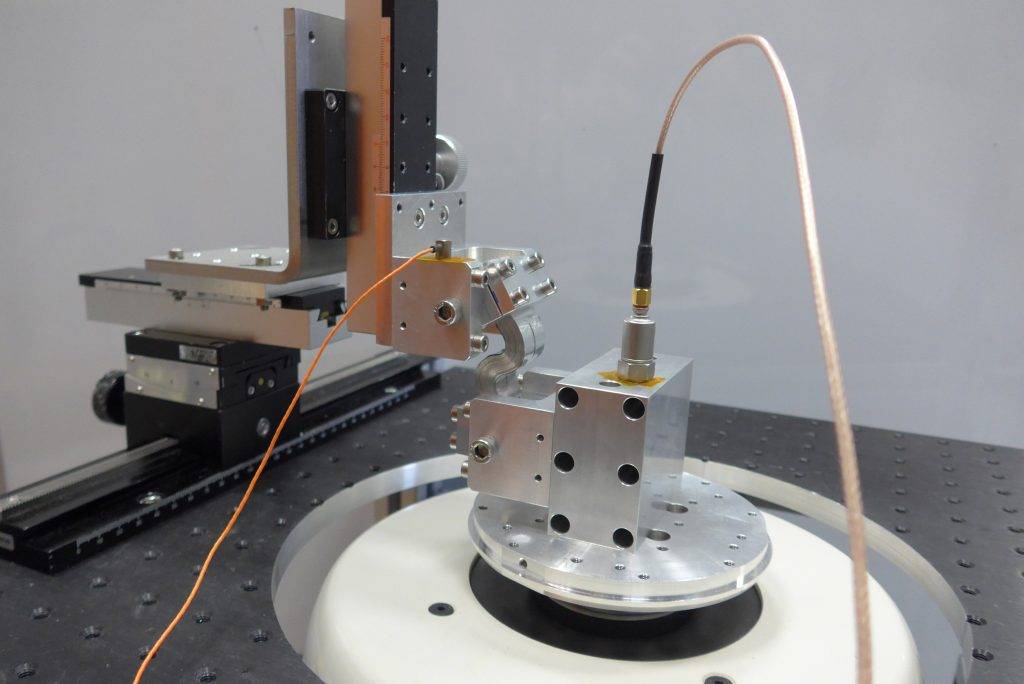

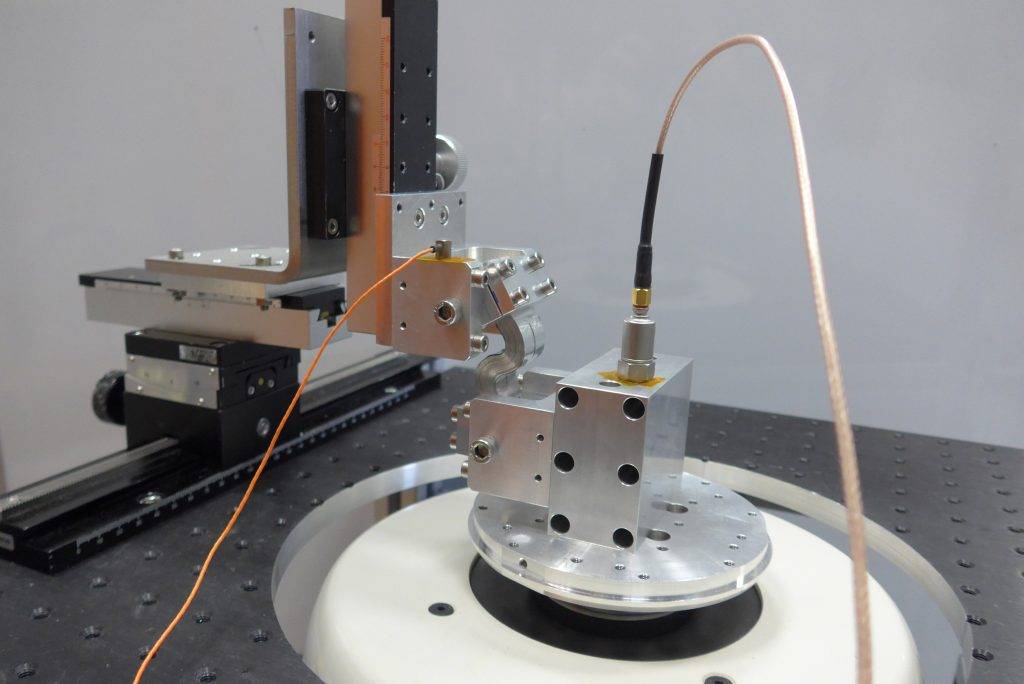

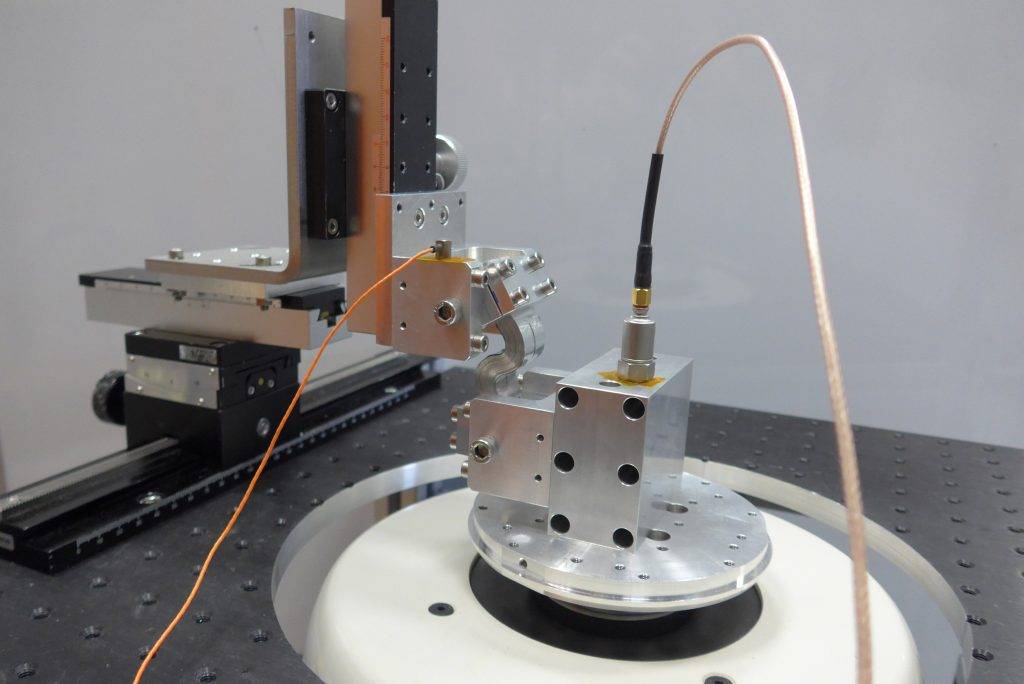

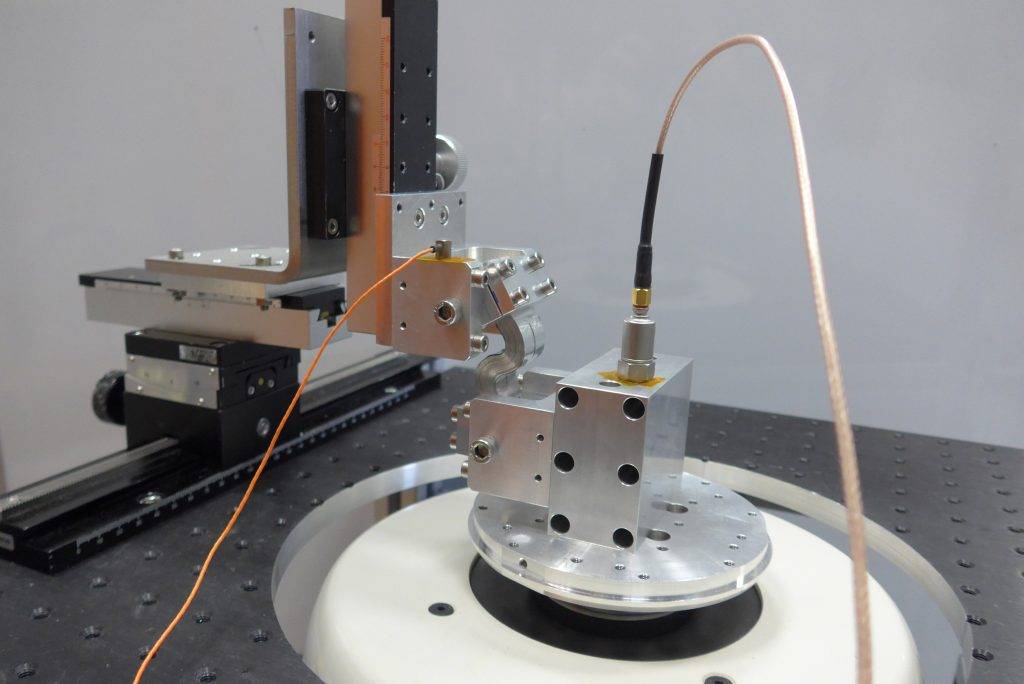

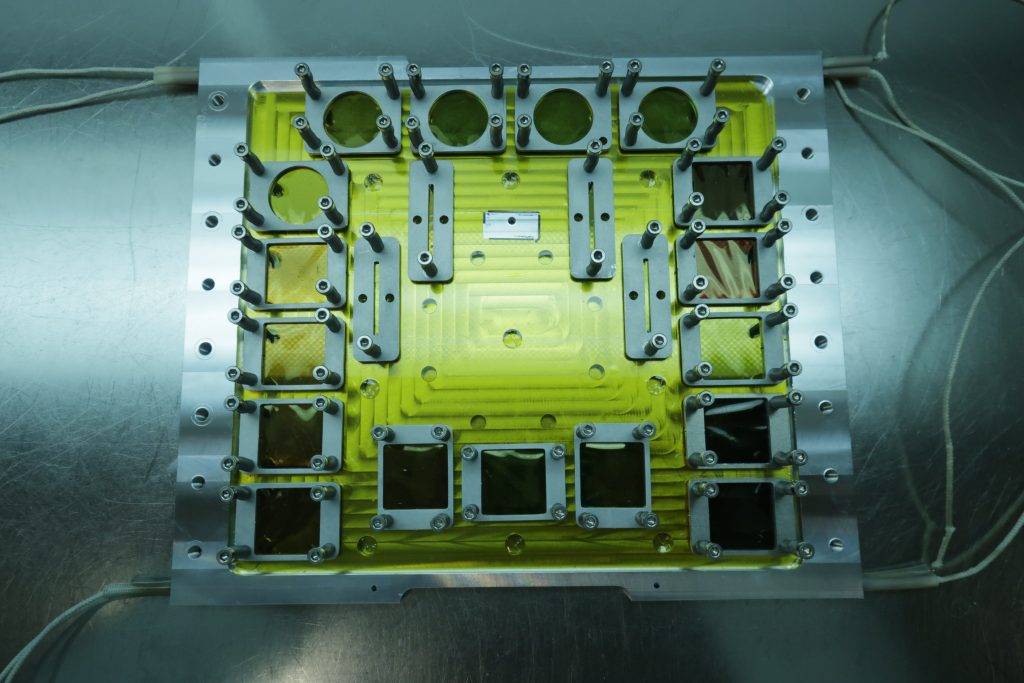

Thermal conductance tests in the temperature range 30K to 200K.

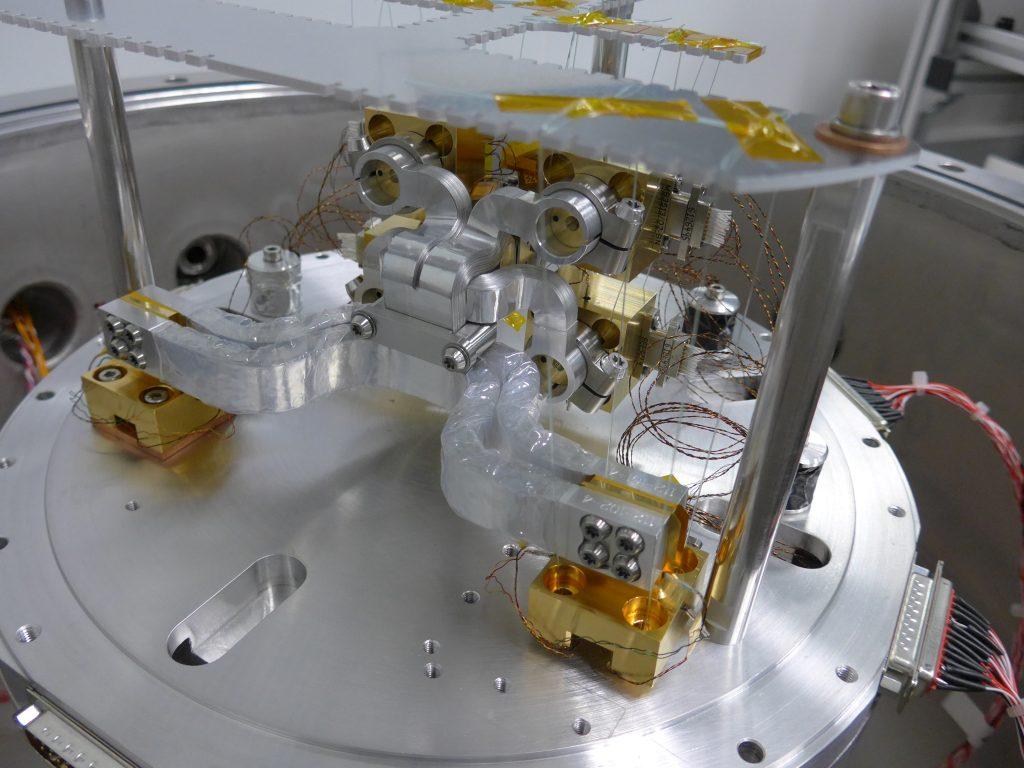

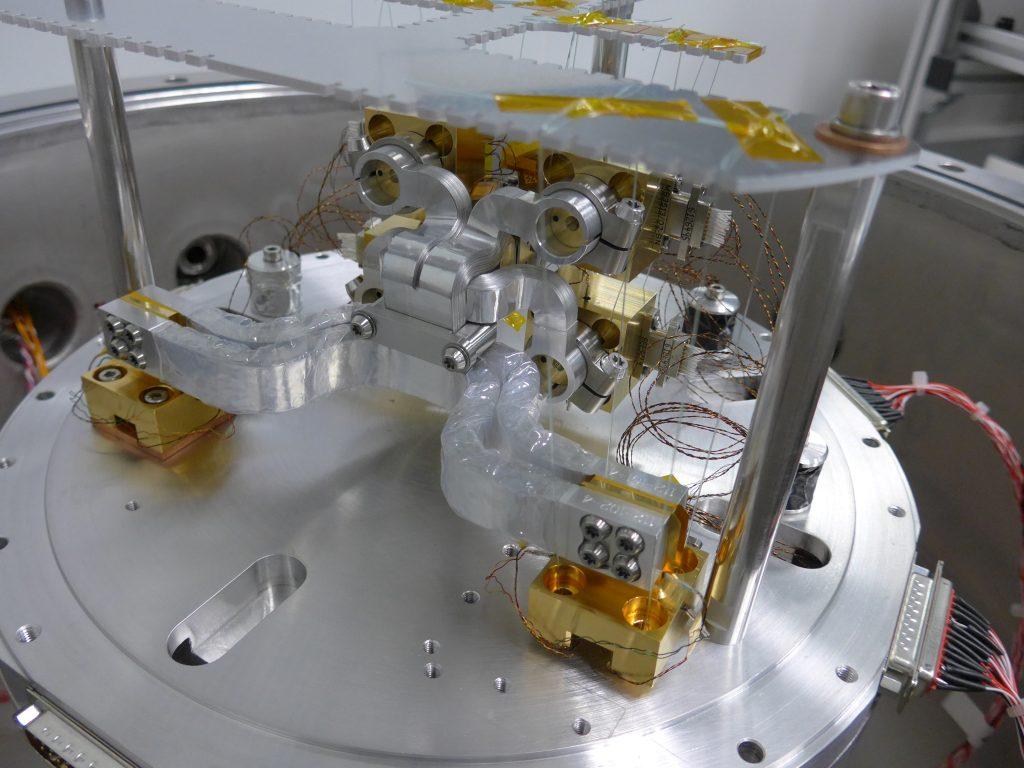

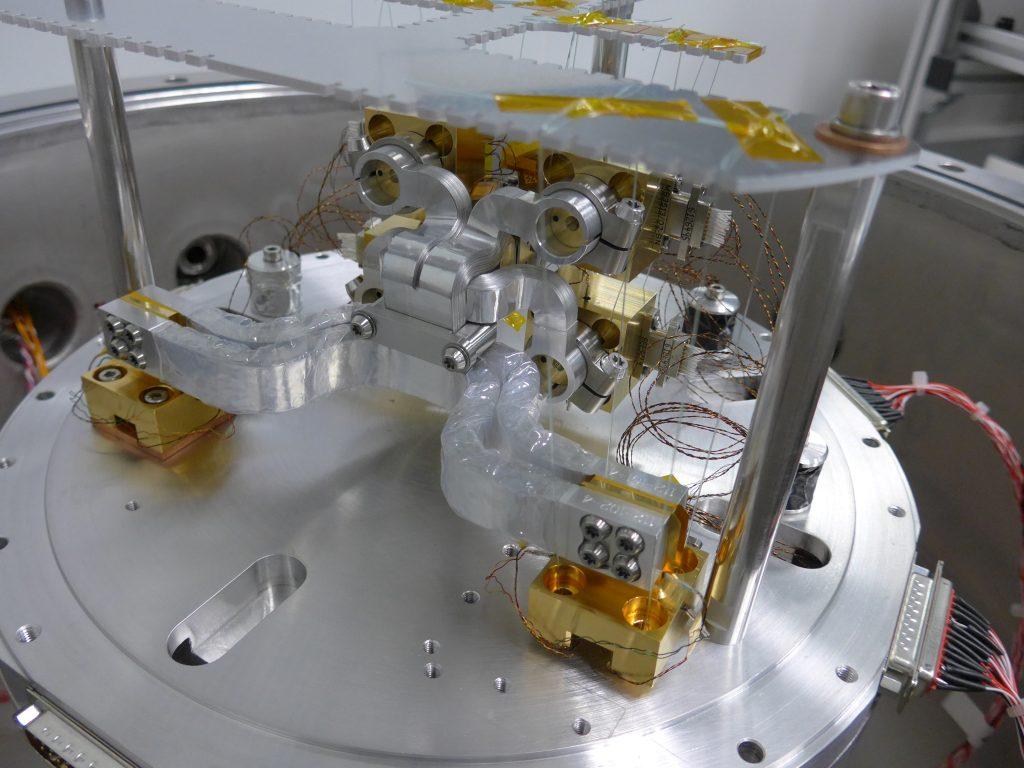

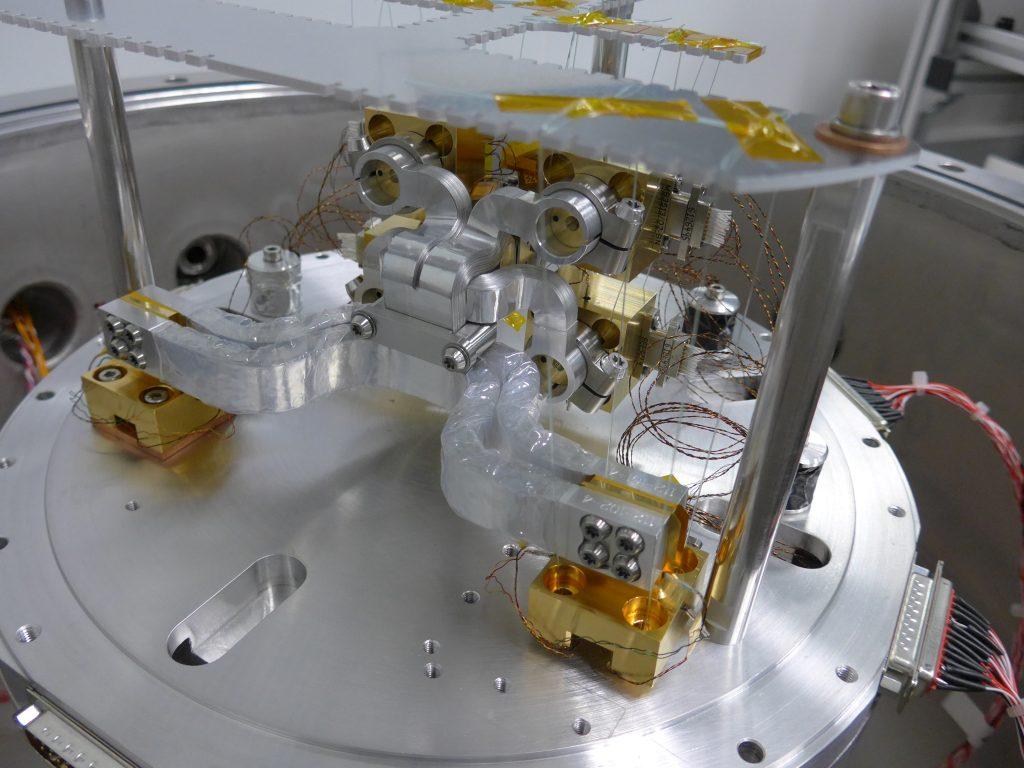

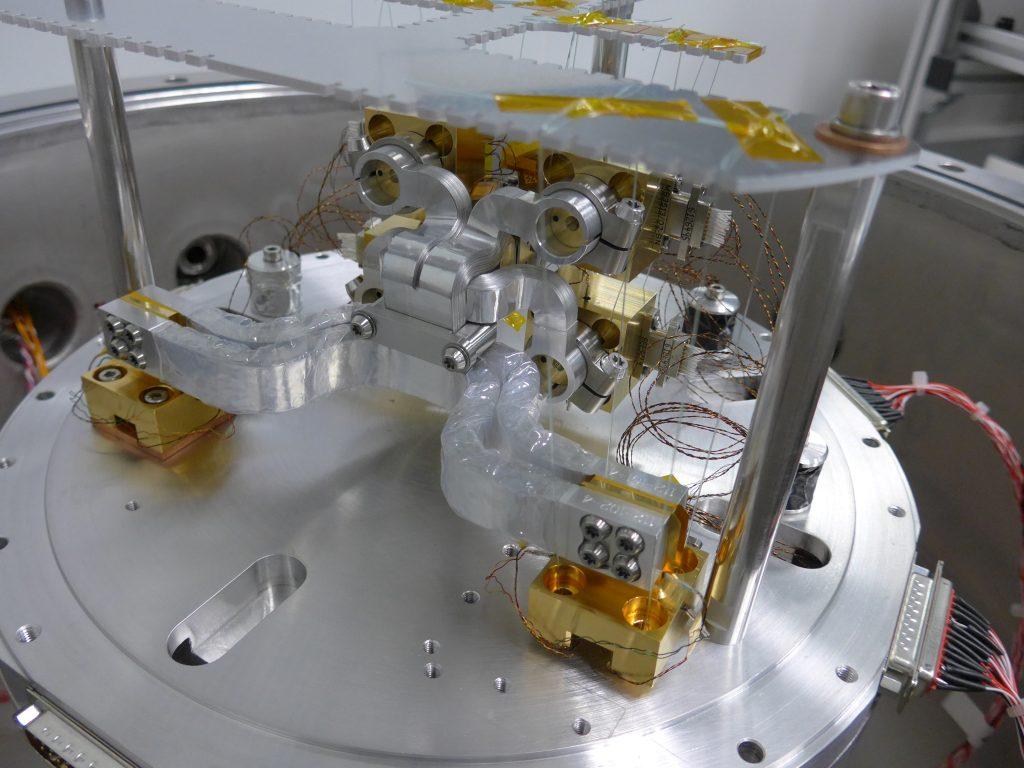

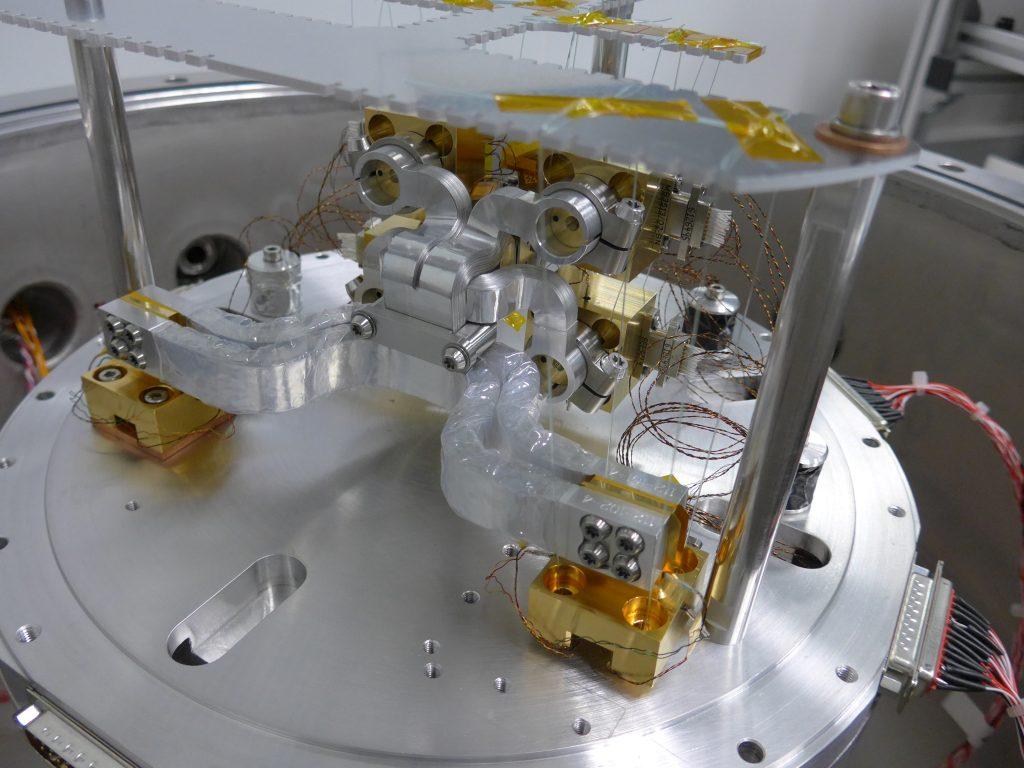

Clean rooms

ISO 8 cleanroom and ISO 5 hoods for the integration of critical components.

Thermal vacuum test benches equipped with Gilfford-McMahon coolers (from 20K to 373K) or a cryogenic cooling loop.

Thermal cycling for sample/process qualification (from 30K to 373K).

Mechanical test benches: stiffness, vibration, damping for structural validation.

Thermal conductance tests in the temperature range 30K to 200K.

ISO 8 cleanroom and ISO 5 hoods for the integration of critical components.

Vacuum test benches

Thermal vacuum test benches equipped with Gilfford-McMahon coolers (from 20K to 373K) or a cryogenic cooling loop.

Thermal cycling

Thermal cycling for sample/process qualification (from 30K to 373K).

Mechanical test benches

Mechanical test benches: stiffness, vibration, damping for structural validation.

Thermal testing

Thermal conductance tests in the temperature range 30K to 200K.

Clean rooms

ISO 8 cleanroom and ISO 5 hoods for the integration of critical components.

Thermal vacuum test benches equipped with Gilfford-McMahon coolers (from 20K to 373K) or a cryogenic cooling loop.

Thermal cycling for sample/process qualification (from 30K to 373K).

Mechanical test benches: stiffness, vibration, damping for structural validation.

Thermal conductance tests in the temperature range 30K to 200K.

ISO 8 cleanroom and ISO 5 hoods for the integration of critical components.

Absolut System ensures cycle repeatability, with precise regulation of the cooling and heating phases, and stabilization at predefined levels. The number of cycles, temperature steps and durations are fully customizable to suit test requirements.

Parasitic flux management: aluminum radiative screen plus MLI.

Attachment: M4 threaded holes with a 20mm by 20mm pitch as standard, or any other option on request.

Test report, cycle records.

Contact us to carry out vacuum qualification testing of components for aerospace programs (ECSS standard).

Absolut System develops high-vacuum and ultra-high-vacuum cryopumping solutions using a closed helium loop.

Development of specific test benches to characterize and optimize electric thrusters in vacuum chambers adapted to a wide range of thrust (mass flow rates). Absolut System has developed modeling and optimization tools for cryopumping systems, enabling optimum results to be obtained for complex geometries.