Today’s SNCF network faces a number of challenges, particularly when it comes to electrifying ultra-dense areas. This technology is a response to the need to increase density in highly constrained geographical areas that do not allow the use of conventional copper cable reinforcement solutions.

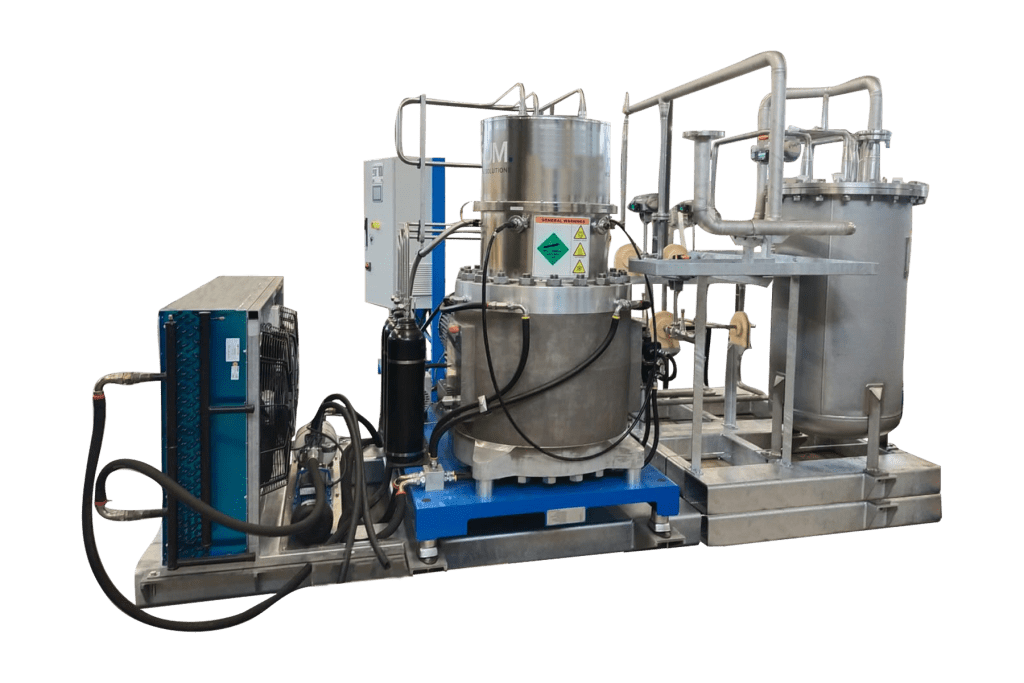

Thanks to its cryogenic expertise, Absolut System supplies the cooling system needed to cool cables to the very low temperatures required for superconductivity.

This innovative technology also reduces the use of copper resources and the amount of work involved. Other benefits of developing this technical solution for the rail industry are the ability to offer power links with no electromagnetic field emissions (no constraints on local residents, no impact on the deployment of technologies such as 5G), and the absence of thermal radiation. These two aspects make it possible to install the power (the superconducting cable) in the immediate vicinity of the control cable (rail signalling), a cohabitation impossible to achieve with conventional solutions.

This technology therefore plays an active role in France’s decarbonization strategy.