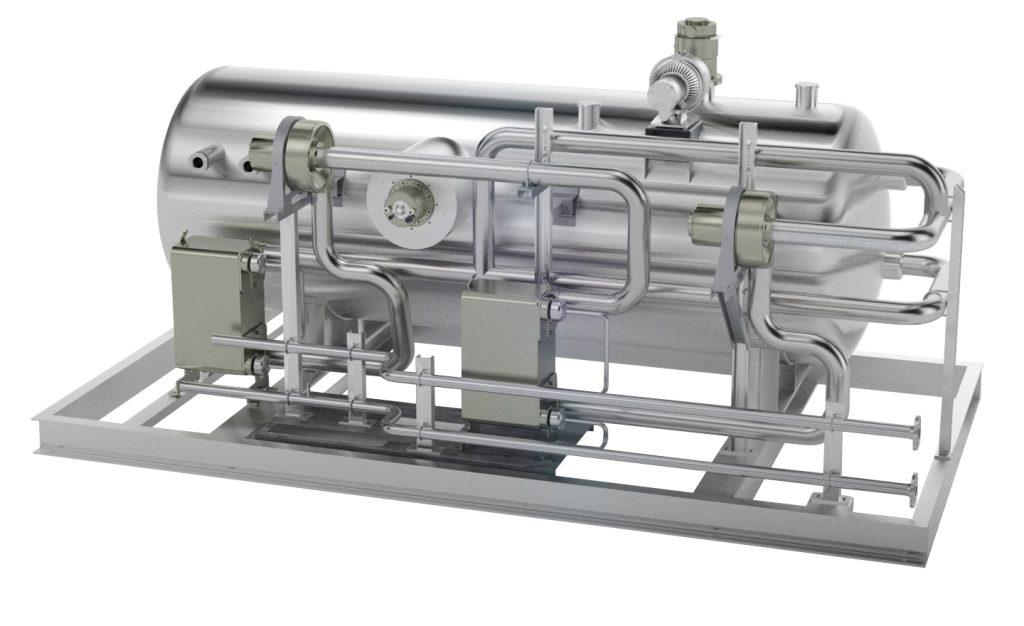

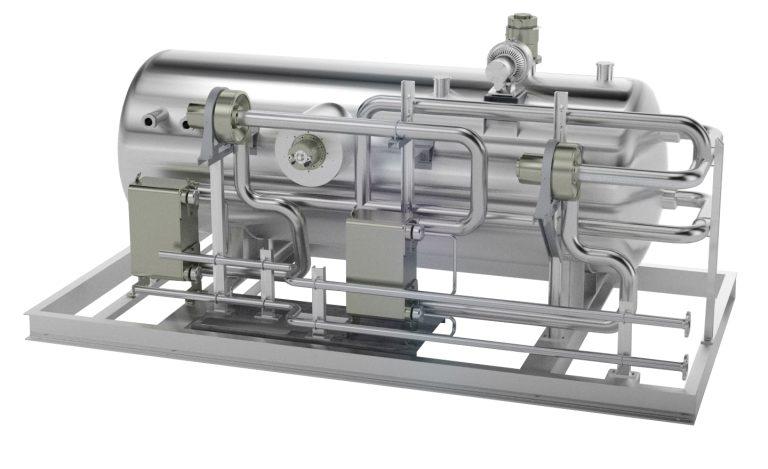

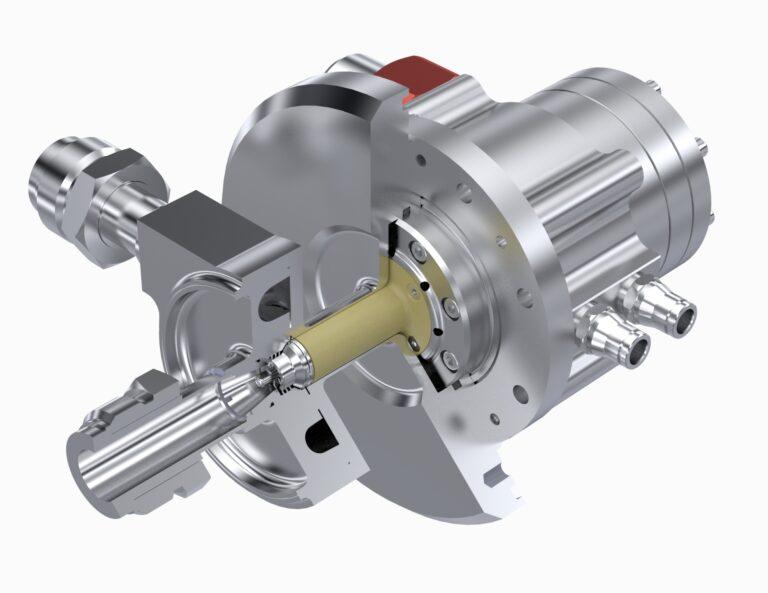

The Turbo-Brayton developed is arranged in a conventional configuration. It consists of a compression brick, a recuperative heat exchanger, usually an expansion turbine, and the thermal heat exchanger, interfaced with the customer’s application (focal plane, detector, heat shield, etc.). The compression brick can have different configurations: usually 2 compression stages, with a two-stage compressor or 2 single-stage compressors. All these components can be integrated into a compact unit, or spread over fairly large surfaces, interconnected by lengths of tubing. Refrigeration can be supplied to multiple loads at a single temperature, or at several different temperatures.