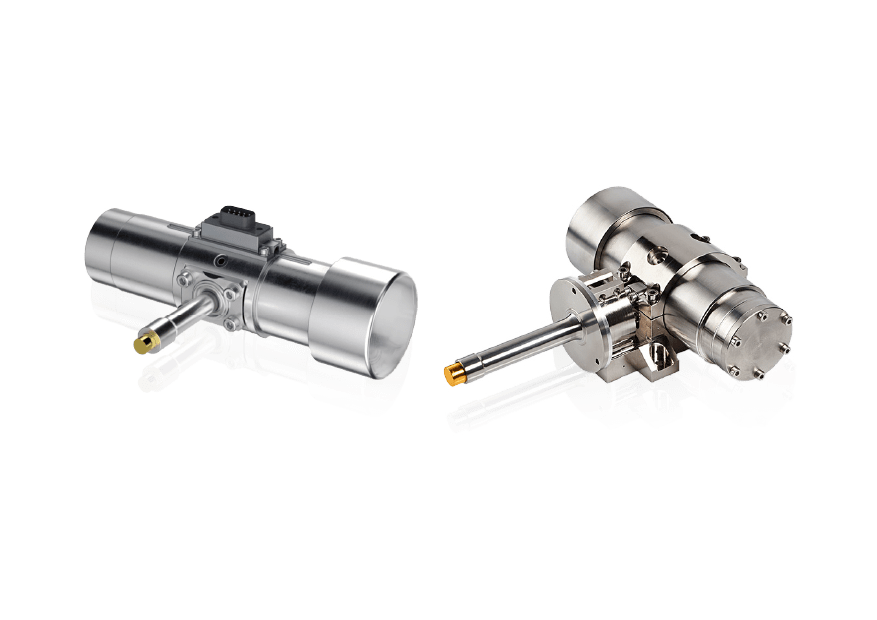

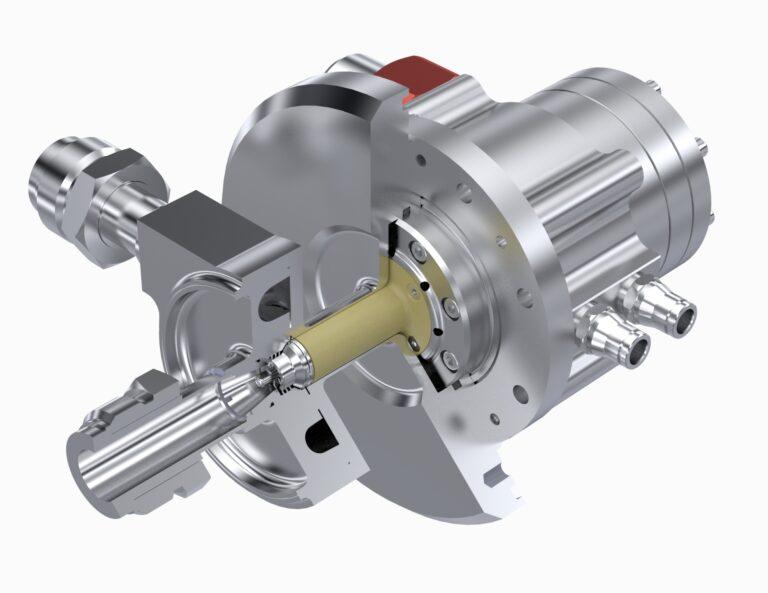

A compact compressor, with a single actuator capable of transmitting motion to 5 compression cells to power the 5 thermodynamic cycles with pressure ratios between 4 and 6 to operate between ambient temperature and 150K. Thanks to hydrodynamic gas bearing technology, the compressor offers maximum miniaturization at a limited development cost.

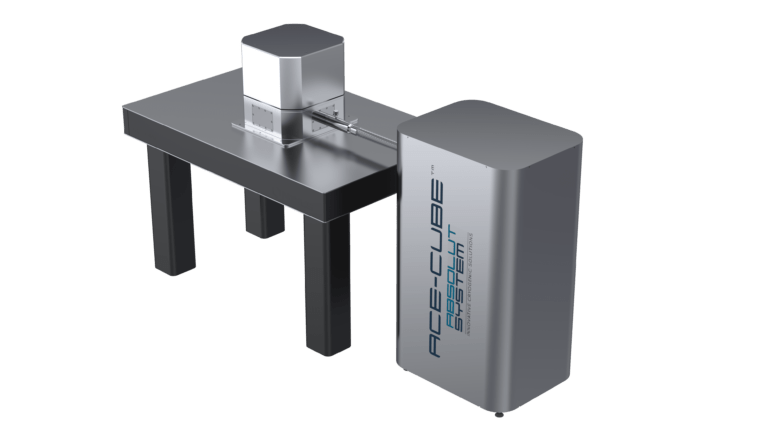

Design: Absolut System has designed a single-cell compressor using MEMS-based non-return valves, in association with Ltd.

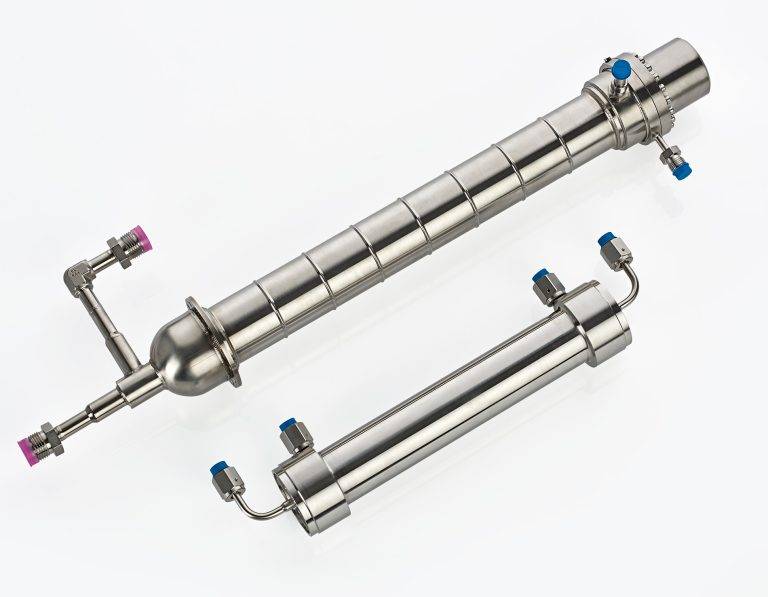

This technology offers very high miniaturization potential, as all cycles can be integrated together. It facilitates the integration of such coolers for embedded systems. Distributed cooling is also facilitated by the targeted miniaturization, with an envelope less than or equal to 18cm3.